Inductors

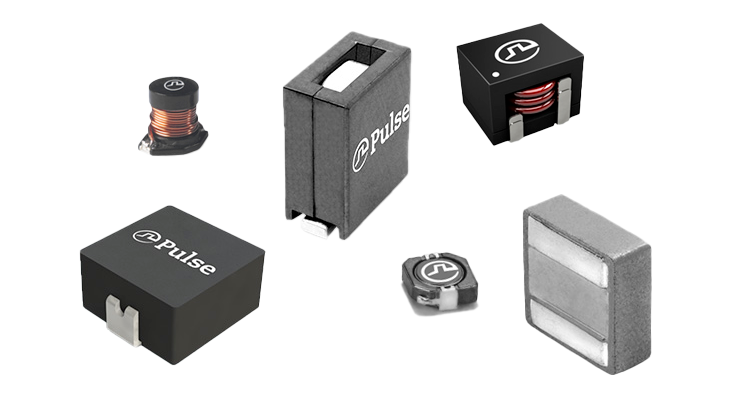

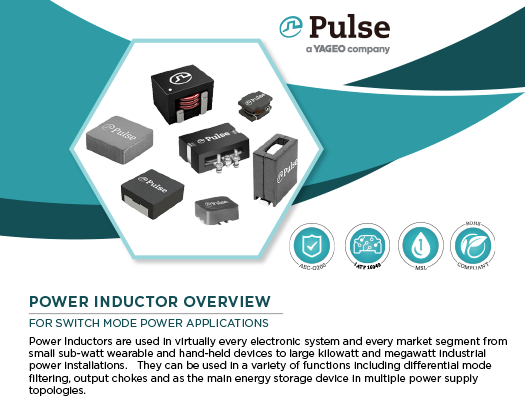

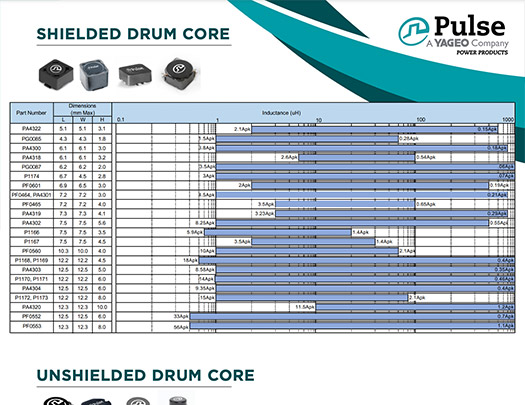

Inductors are used to store energy or filter out unwanted signals in both power and signal communication applications. The key parameters are current rating, saturation current, impedance versus frequency, SRF and Q value as well as minimizing of AC losses in power applications. Pulse solutions include; RF Signal Inductors, EMI Suppression Beads and Power Inductors and come in a wide range of constructions including multi-layer, chip, molded & composite, power beads, drum cores and wire-wound technologies.

Pulse solutions range from mA to 150Arms.